Our Products

Sarvosmi ERX – RMSC: Real-Time Raw Material Supply Chain Software

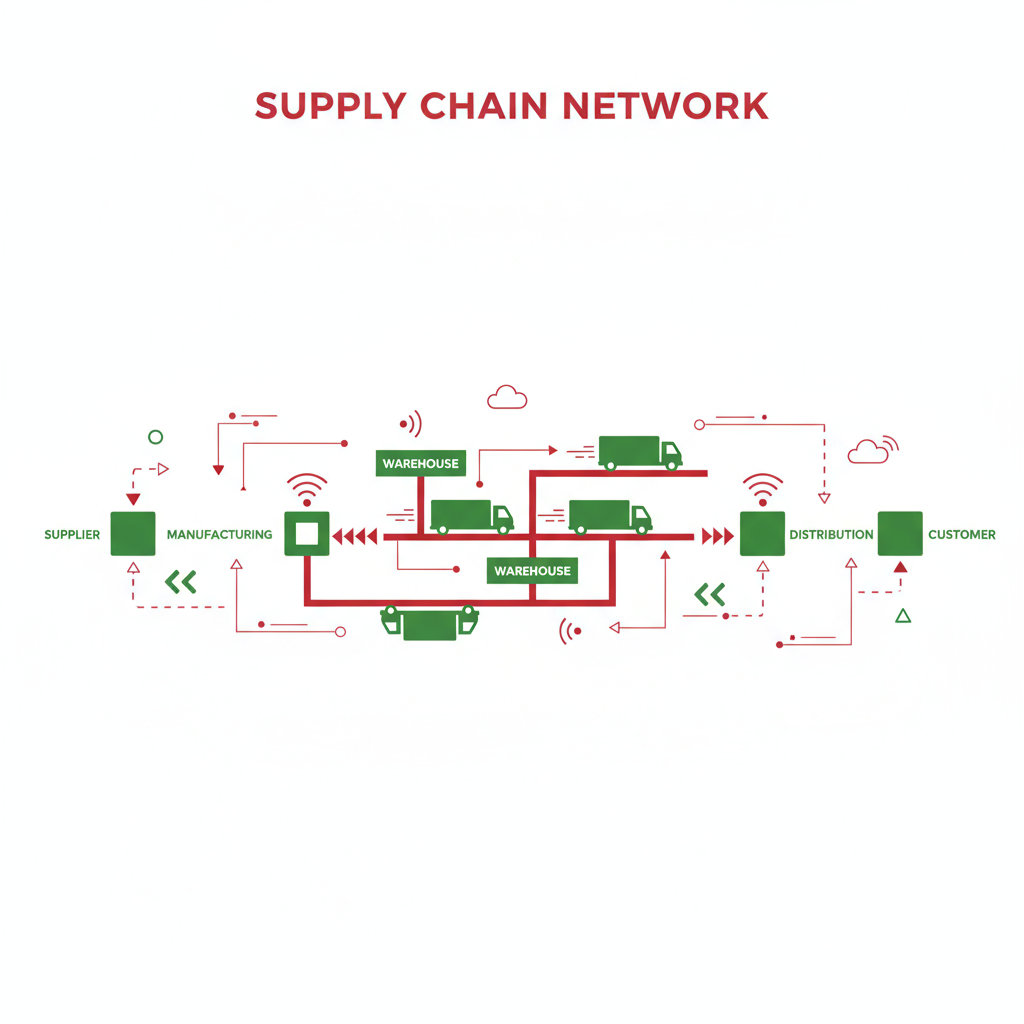

Revolutionizing Supply Chain Management

Our comprehensive solution addresses every aspect of raw material supply chain management, from demand generation to final delivery.

Sarvosmi ERX – RMSC

Sarvosmi ERX – RMSC addresses execution of Raw Materials processes right from Raw Material demand generation against production plans to Right-in-Time (RIT) procurement of Raw Materials to Just-in-Time (JIT) receipt of Raw Materials to Quick and accurate unloading of consignments to Fast inward QC and / or inspection of incoming Raw Materials to Quick & Accurate storing of QC OK Raw Materials to Timely & accurate issuing and delivery of Raw Material to Production Line / Stage Rejections & Returns from Unloading to Inward QC to Inline rejections or Production Plan short closure Material Re-issue against Damaged or wrong part Returned WIP material …. all in real-time with appropriate alerts. The key benefit being optimizing of all processes resulting in lower transaction & operational costs.

Modules

Master Data Modules

- Organization Administrator

- Calendar

- Users

- Raw Material Store

- Unloading Dock

- Raw Material "Items"

- Supplier

- Purchase Order

- Bill of Materials (BOM)

- Reason

Transactional Modules

- Production Plan Execution (PPE)

- Advance Shipping Notice (ASN) - Suppliers

- Material Requirement Generation

- Advance Shipping Notice (ASN) - Buyers

- Gate Receipts

- Docking & Unloading

- Inward QC & Inspection

- Rejections & Returns

- Picking & Putting Operations

- Material Issue & Delivery

- In-line Rejections & Returns